Hydraulic fittings may not be the most exciting topic, but they are critical components of hydraulic systems. They connect different parts of the system and help regulate the flow of fluids. In this article, we’ll take a closer look at what hydraulic fittings are, how they work, and why they are important.

What are hydraulic fittings?

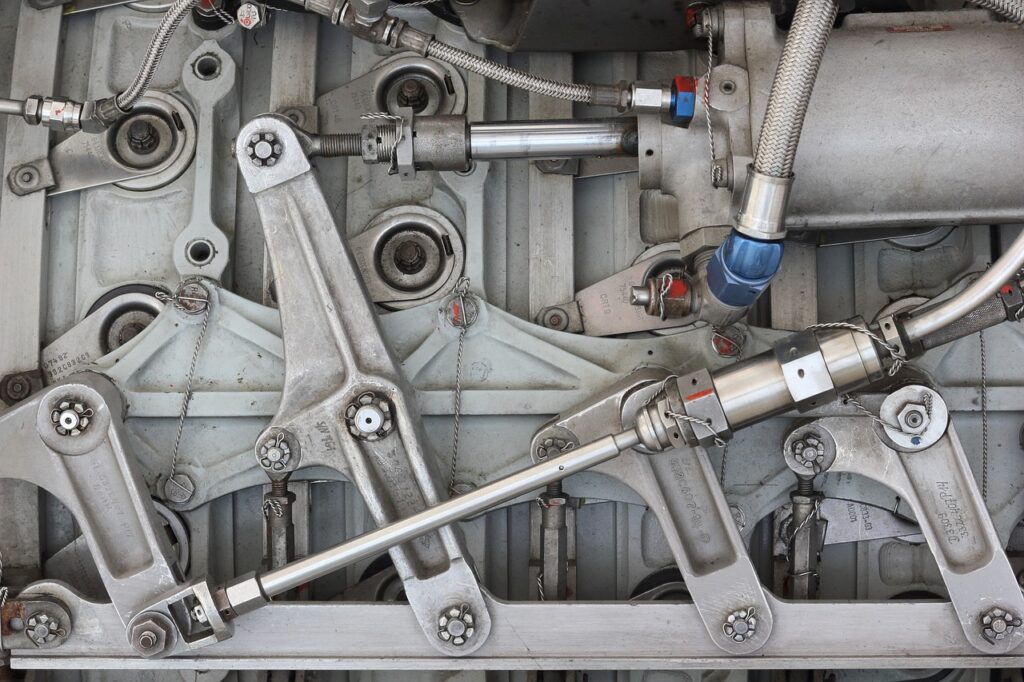

Hydraulic fittings are parts that connect different components of a hydraulic system. They are used when pipes, hoses, or tubes need to be joined together. Fittings can also be used to regulate the flow of fluids in the system. They come in many shapes and sizes, depending on their purpose and the types of components they are connecting.

How do hydraulic fittings work?

Hydraulic fittings work by creating a secure connection between two or more parts of a hydraulic system. They are designed to be strong and durable to withstand high pressures and temperatures. Most fittings use threads to create a tight seal between the components. When the fitting is tightened onto a pipe or hose, the threads compress and create a seal that prevents fluid from leaking out.

Why are hydraulic fittings important?

Hydraulic fittings are a crucial component of hydraulic systems. Without fittings, it would be difficult to connect different parts of the system together. Fittings are also important for regulating the flow of fluids in the system. By controlling the flow of fluids, fittings can ensure that the system runs smoothly and efficiently.

What are some common types of hydraulic fittings?

There are many different types of hydraulic fittings, each with a specific purpose. Here are a few of the most common types:

- Adapters: Adapters are used to connect hoses or pipes with different thread types or sizes. They allow components with different threads to be connected together.

- Couplings: Couplings are used to join two hoses or pipes together. They are often used in areas where the hoses or pipes need to be disconnected frequently.

- Elbows: Elbows are fittings that allow pipes or hoses to be joined at an angle. They are useful in tight spaces where pipes or hoses need to be routed in a specific way.

- Tees: Tees are fittings that allow a pipe or hose to split into two separate lines. They are often used in hydraulic systems to split the flow of fluid.

How do you choose the right hydraulic fitting?

Choosing the right hydraulic fitting depends on several factors. First, you need to consider the type of components you are connecting. Make sure the fitting is compatible with both components and can handle the pressure and temperature of the system. You should also consider the size and shape of the fitting, as well as the thread type.

When installing hydraulic fittings, it’s important to use the right tools and follow the manufacturer’s instructions. Make sure you have the correct wrenches and other tools for the job. Always use the recommended torque specifications when tightening fittings to prevent leaks and ensure a secure connection.

Hydraulic fittings may not be the most thrilling topic, but they are essential for hydraulic systems to function properly. They connect different parts of the system and help regulate the flow of fluids. By choosing the right fittings and following proper installation procedures, you can ensure your hydraulic system will run smoothly and efficiently.