High-quality lighting is a must-have in industrial and warehouse facilities to ensure activities run smoothly and to guarantee workers safety. Apart from complying with safety and material code standards, an ideal industrial lighting system should be able to withstand harsh environmental conditions such as humidity, extreme temperatures, vibrations and corrosive substances. This guide sheds light on the factors you need to consider when choosing conveyor lighting systems.

Durability and maintenance

Today, warehouse facility managers have technology to thank for the vast array of lighting options and equipment available on the market. LED systems are suitable for warehouses and industrial facilities because they consume only a third of energy and require 90% less maintenance than traditional lamps. The fact that LED systems can have up to 50,000 hours of useful life makes them a worthwhile investment for manufacturing, warehousing, processing and mining sectors.

Level of illumination

Lumen rating is defined as the amount of light that a light source is capable of producing. The level of illumination desired often depends on the nature of the task at hand. A typical conveyor belt requires roughly 40 lux of light. It is imperative for manufacturing, processing and mining plants to maintain an excellent level of illumination at all times. Having sufficient illumination can significantly reduce accidents and improve productivity in industrial sites.

Colour rendering

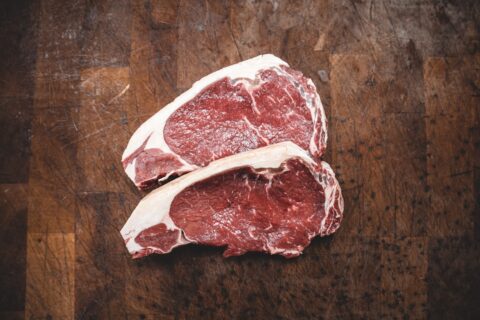

Colour rendition is crucial in the food and beverages processing sectors. Colour rendering refers to the ability of a light source to represent the true colour of an item accurately and is often measured using the colour rendering index (CRI). Investing in a high colour rendering lighting system allows workers to perform their jobs effectively while guaranteeing the essential quality of food and beverage products.

Durability

Due to the nature of their working environments, conveyor luminaires should be able to withstand extreme temperatures, dirty power, corrosive chemicals and vibration from heavy industrial plants. Voltage and current fluctuation is a common problem in many industrial sites. These spikes in power often occur due to lightning strikes and a multitude of defects in power devices.

Prolonged exposure to dirty power can compromise the performance of your industrial lighting system. You should, therefore, consider investing in a resilient conveyor power solution to counteract the effects of dirty power use. Where extreme temperatures of above 50°C are involved, consider luminaires that employ advanced vapour chamber-based cooling.

Adaptive light specification

Nowadays, thanks to the use of occupancy sensors and timers, it is possible to adapt your lighting equipment to your working environment. The advantage of having an adaptive lighting system is that you can track real-time power usage as well as maintenance data. Consider investing in conveyor luminaires that have the adaptive and remote monitoring features.