Designing PCB layouts for medical devices is crucial for functionality and safety. A well-designed layout can enhance performance while providing good protection against interference. Medical device PCB layout design is not an easy task, so some guidelines can help designers achieve success in their projects.

Firstly, designers must follow the industry standards and comply with regulations. Medical devices undergo rigorous testing, so it is important to ensure they meet safety and performance criteria. Thus, designers need to follow the guidelines prescribed by organizations such as The International Electrotechnical Commission IEC and The Food and Drug Administration FDA. These organizations regularly update their safety requirements to ensure high levels of safety and performance.

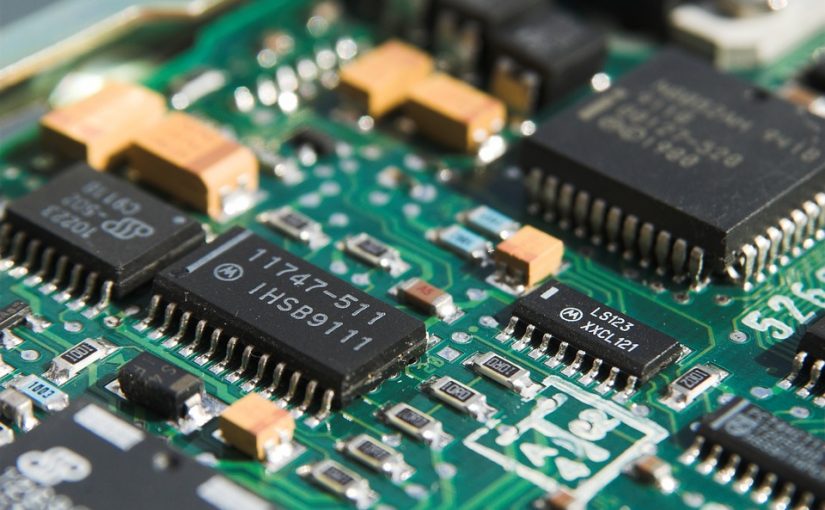

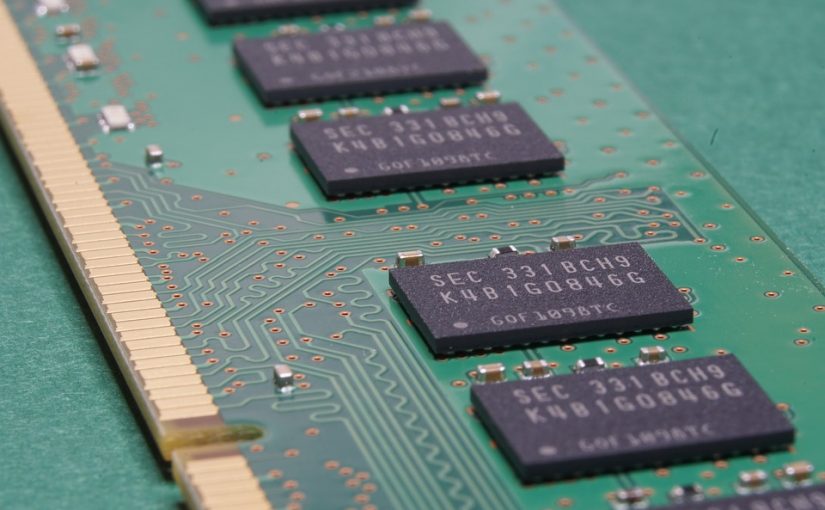

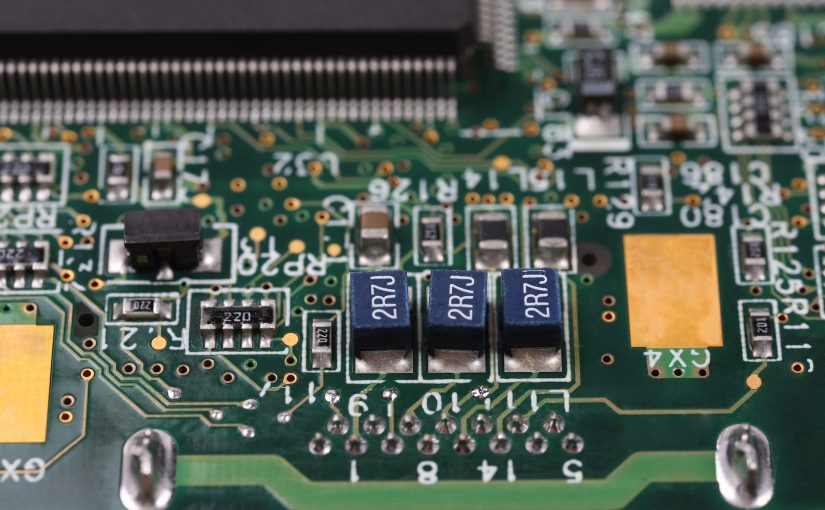

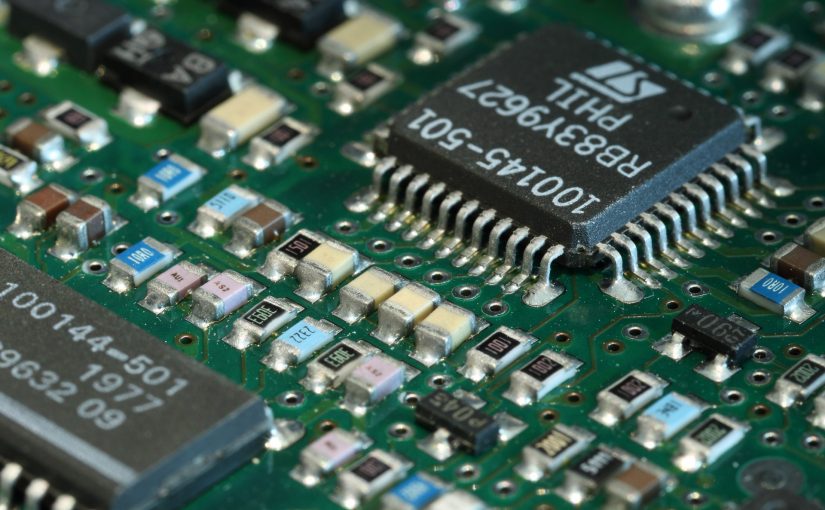

Secondly, designers should consider components’ placement on the circuit board. When designing a medical device PCB layout, the location of components such as capacitors, resistors, and power inputs should be carefully considered. Signal path lengths and signal integrity are crucial for measurement accuracy, so placing the components’ carefully is important. Signal interference can cause serious mistakes in measurements and possibly hazardous outcomes.

Thirdly, designers should keep the patient in mind when designing a medical device PCB layout. A device’s components should be designed in such a way that they do not cause harm, are reliable, and resistant to errors. Thus, the layout should prioritize a patient’s safety, focusing on both the device’s physical and electrical safety. A well-designed layout can help prevent patients from getting shocked or burned.

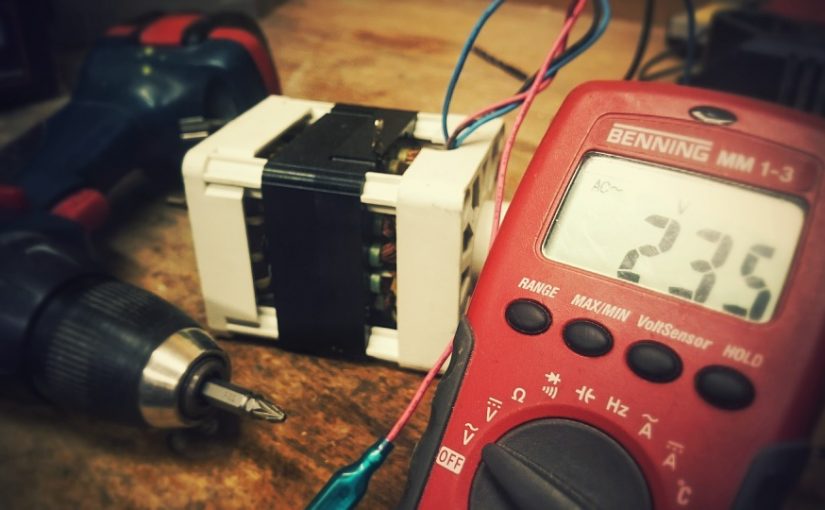

Fourthly, designers should choose components that maximize the device’s performance while minimizing interference. While selecting components, designers should consider factors such as cost, temperature rating, and dissipation. A device’s performance can be greatly enhanced by selecting the right components and placing them in the right location with enough space around them. Doing this will ensure good current conduction, reduce the likelihood of short circuits, and help with heat dissipation.

Lastly, designers should consider the size of the circuit board. Size is an important factor in medical devices because they are often small. It is important to design the PCB layout so that it is as small as possible while still retaining circuit functionality. Keeping the layout precise can help minimize the device’s overall size, which makes it more convenient and improves usability.

Medical device PCB layout design is a critical component to ensure safe and efficient performance. The guidance and industry standards provided by organizations such as IEC and FDA help ensure that PCB layouts are safe, reliable, and perform accurately as intended. With careful considerations regarding component placement, patient safety, and performance, designers can create a layout that reduces interference, maximizes efficiency, and enhances overall device functionality. Bearing in mind that a device’s size is an important factor, creating a small and efficient layout can greatly improve a device’s usability while ensuring it is working appropriately. The PCB layout of medical devices plays a crucial role in ensuring safety, accuracy and performance.