Pallets: The Backbone of Shipping

When it comes to transporting goods across the country, pallets are an essential component of the process. Whether you are

When it comes to transporting goods across the country, pallets are an essential component of the process. Whether you are

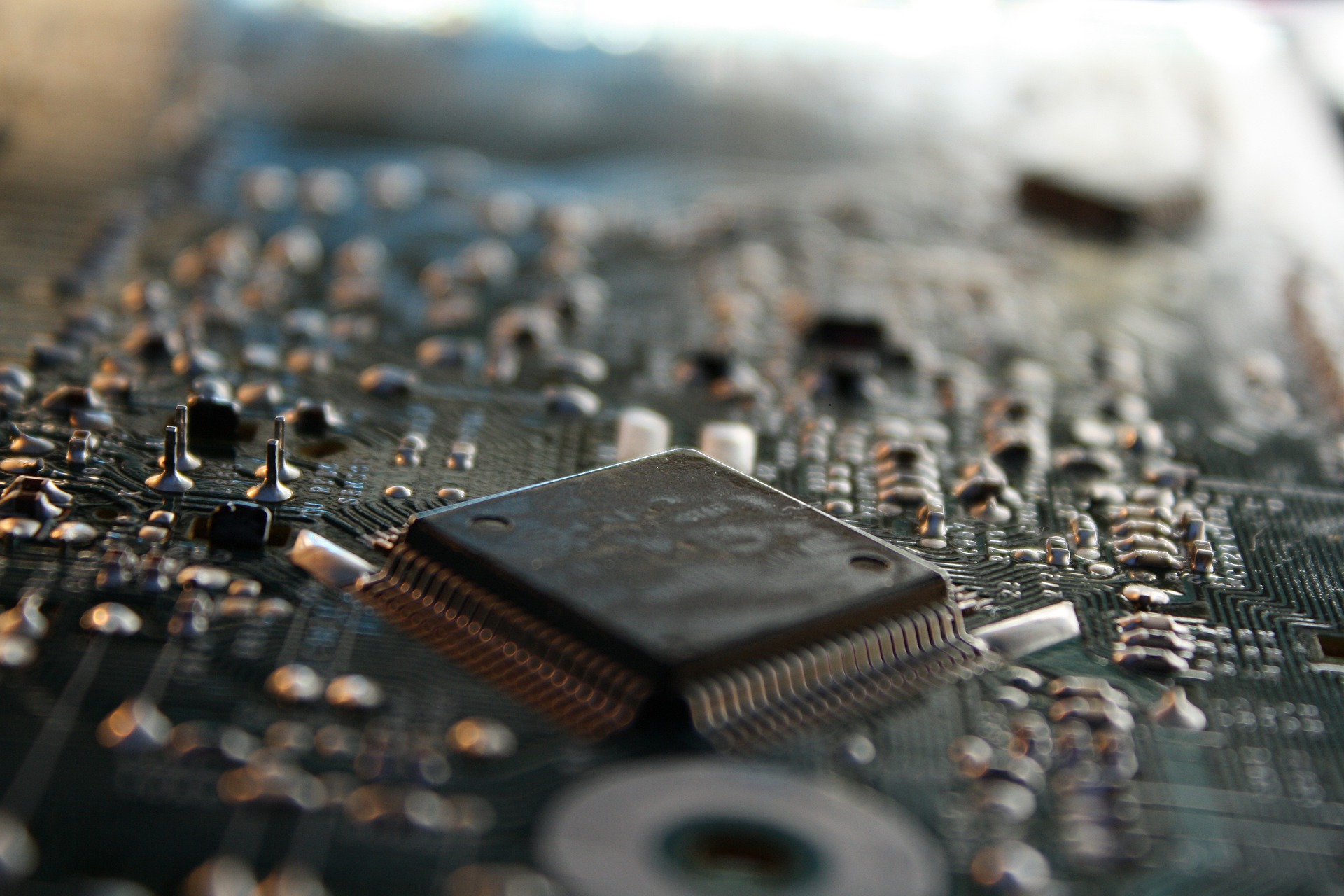

Aluminum Printed Circuit Boards are one of the most popular electronic circuit boards available today. These boards are lightweight, resistant

Planning a birthday party is a lot of fun. Not only it is time to celebrate your child’s birthday, but

Wrought Iron Shutters are found mostly on a Tuscan styled or old-world designed homes but can be made to suit

A refrigerator gasket is the white, flexible ring on the edges of the refrigerator door that control the leakage of

Hand Crafted Bricks dates back to about 7000 BC as ruins have been found in Turkey on the site of

The paving material you choose can literally make or break your garden. The first few things that strike people’s minds

Acrylic is a sturdy transparent material that can be used as an alternative to glass due to its glasslike nature.