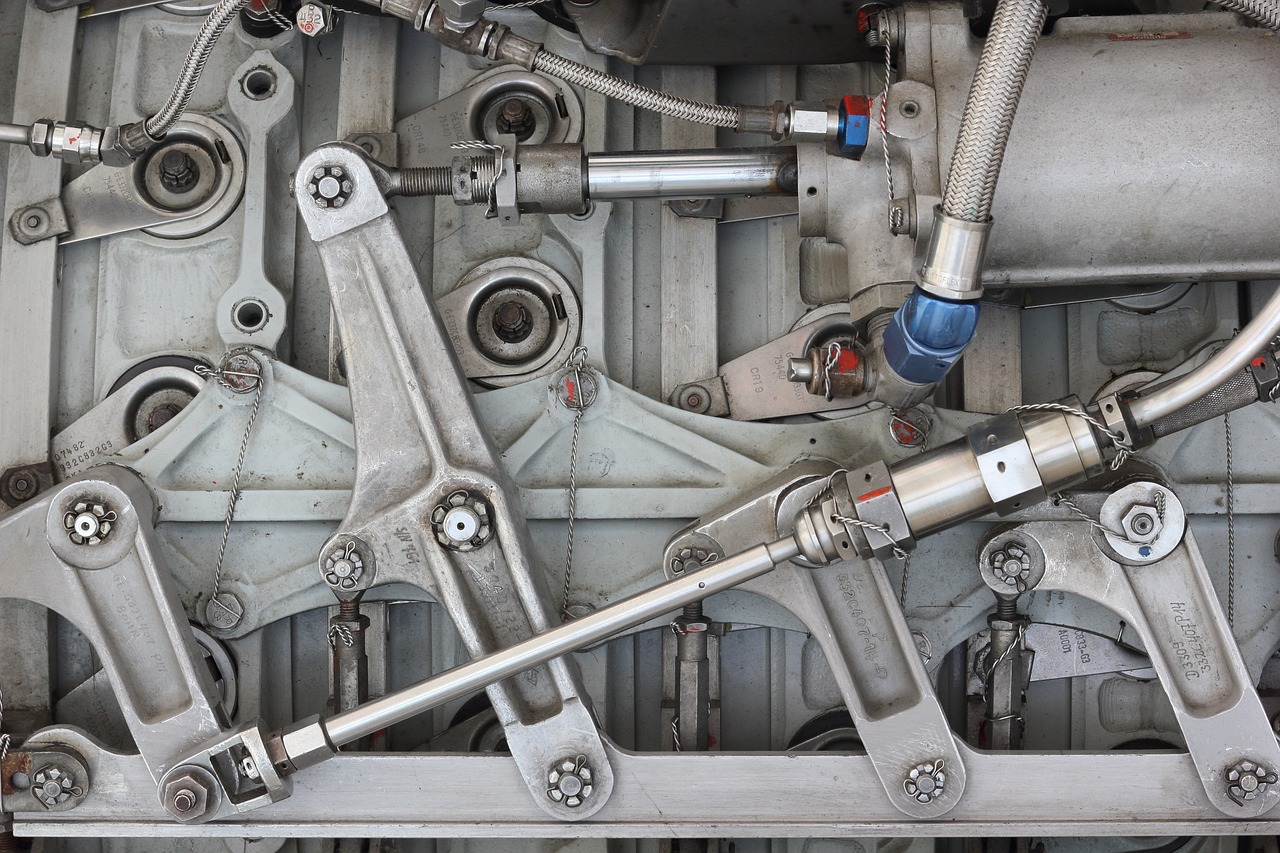

Hydraulic fittings are important components in fluid power systems that facilitate the transfer of fluid from one point to another. These fittings are designed to connect different sections of hydraulic hoses, pipes, and tubes to create a unified system that can handle high-pressure fluids. Hydraulic fittings come in different shapes and sizes, and they are made from various materials such as steel, brass, and plastic. In this article, we will look at some of the common types of hydraulic fittings, their applications, and the materials used to make them.

One of the most popular types of hydraulic fittings is the coupler. This fitting is used to connect two hydraulic hoses together and is essential for creating a fluid power system that can be easily maintained. Couplers are designed to be easily disconnected without having to drain the entire hydraulic system. The two main types of couplers are push-to-connect and screw-to-connect, with the former being more popular because of its ease of use.

Another common type of hydraulic fitting is the elbow. This fitting is used to change the direction of fluid flow in a hydraulic system. Elbows are usually made from brass or steel and come in different angles such as 45 and 90 degrees. They are commonly used in fluid power systems to connect straight hoses and pipes for easier installation.

Hydraulic adapters are also important fittings that are used to connect hoses and pipes of different sizes and shapes. Adapters are designed to create a secure and leak-proof connection between two components. They come in different styles and materials, and their applications vary depending on the system requirements.

Hydraulic fittings are typically made from various materials depending on the required performance and application. Steel fittings are the most common and are usually used in high-pressure hydraulic systems. Stainless steel fittings are also popular because of their corrosion resistance and durability. Brass fittings are used in low-pressure applications and are less expensive compared to steel fittings. Plastic fittings are also available and are ideal for applications where weight is a factor.

It is important to note that hydraulic fittings require proper installation and maintenance to function effectively. Fittings that are not correctly installed can lead to leaks, which can cause damage to hydraulic components and pose safety hazards. Regular maintenance of hydraulic systems is necessary to identify and fix any problems with fittings, hoses, and pipes.

When choosing hydraulic fittings, there are several factors to consider, such as operating pressure, temperature, and compatibility with the fluid being transferred. It is essential to select fittings that meet the system requirements for maximum efficiency and longevity. It is also important to ensure that the fittings are installed correctly and that they are compatible with other components in the system.

Hydraulic fittings are essential components in fluid power systems. They are designed to facilitate the transfer of fluid from one point to another while maintaining the integrity of the system. With various types of fittings available in different materials and styles, it is essential to select the right fitting for the job. Proper installation and maintenance are also necessary to ensure the effective and safe operation of hydraulic systems.