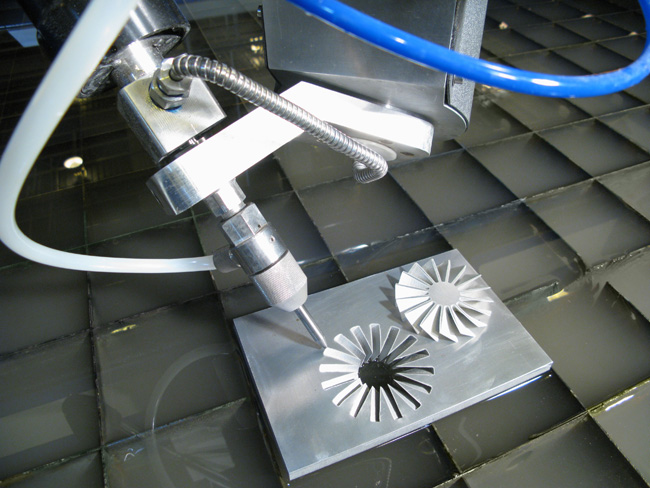

With Computer Numerical Control (CNC) machines it is possible to craft industrial components without the help of a human. These machines are automated milling devices. CNC machines use coded sets of instructions that are sent via an internal computer. This allows the machines to manufacture parts quickly and more effectively. Most of these machines are used large scale in industries and manufacturing, however, some are available for hobby uses in private homes. A wide variety of these devices exist from plasma cutters to more simple drills, which allows them to manufacture a wide range of parts.

CNC Machine Types

Milling machines, lathes, and grinders are the most common types of CNC machines. For cutting materials such as metal, milling machines can move their spindles to a different position and depth, according to the directions given by the computer. Lathes shape material by using automated tools. They are relied upon to make more detailed cuts in pieces like cones and cylinders, or other symmetrical work. Grinders are the preferred machine type for grinding down materials, such as plastic or metal, when a specific shape is desired. They use a spinning wheel for grinding. These are easily programmable and are desired for projects that do not require as much precision in their work, as opposed to mills or lathes. CNC routers are used when cuts are required in various materials, as well as 3D printers that are computer programmable. This same technology can be used in conjunction with different types of cutters, such as those that are used with plasma, lasers, and water.

Milling machines, lathes, and grinders are the most common types of CNC machines. For cutting materials such as metal, milling machines can move their spindles to a different position and depth, according to the directions given by the computer. Lathes shape material by using automated tools. They are relied upon to make more detailed cuts in pieces like cones and cylinders, or other symmetrical work. Grinders are the preferred machine type for grinding down materials, such as plastic or metal, when a specific shape is desired. They use a spinning wheel for grinding. These are easily programmable and are desired for projects that do not require as much precision in their work, as opposed to mills or lathes. CNC routers are used when cuts are required in various materials, as well as 3D printers that are computer programmable. This same technology can be used in conjunction with different types of cutters, such as those that are used with plasma, lasers, and water.

Operation and Programming

G-code is the common code used in the programming of CNC units. This code gives information about where machine parts should be positioned and it reveals to the machine exactly where to place the tools. Additional details it gives the machine include the speed a part needs to run at, how deep the cuts should be, as well as burns or punches, and the automated tool’s angle. With today’s technology, most industrial CNC machines are connected to a network of other computers and get their operating and tooling instructions through a software file.

Pros and Cons

Whole cells of tooling machines can be connected together in the industrial setting and still work independently of one another. Digital designs drive them, eliminating the need for a physical drawing of a design blueprint. In fact, many can work for several days without the intervention of a human being. Some even go so far as to being able to place a call or send a text message to an operator’s phone if a malfunction has occurred. The automated features provided by a CNC motion controller allow the operator to not have to supervise the machine, which frees them up to complete other tasks on the job.

In a factory setting, errors are common when things are cut by hand using different tools. However, with a CNC machine, precision and reliability are expected due to the computer controls. They can also work non-stop without becoming tired. Waste is eliminated and accuracy is almost guaranteed.

CNC machines are, however, expensive, especially compared to their older counterparts. For smaller businesses they can be completely unaffordable, as well as being expensive to maintain and repair. In addition, a skilled workforce with specialty training is required to run these machines. As accurate as the machines are, there is still room for an error to occur, especially if the operator is in error or the equipment is not repaired and kept up to date.

Dodge visitor traps: Certain eateries cook only to sightseers! The greater part of the times this means higher costs, and a restricted, less bona fide menu. In some cases the quality is likewise not the best as those eateries put money on the thought that the travelers have little experience of their sustenance and in any case they will leave sufficiently quick not to give them an awful notoriety.

Dodge visitor traps: Certain eateries cook only to sightseers! The greater part of the times this means higher costs, and a restricted, less bona fide menu. In some cases the quality is likewise not the best as those eateries put money on the thought that the travelers have little experience of their sustenance and in any case they will leave sufficiently quick not to give them an awful notoriety.

The rate of interest charged on home loans is also affected by the prevailing rate of inflation. However, only adjustable rate mortgages (ARMs) can be affected by inflation. If you apply for an adjustable rate mortgage, which is adjusted annually for inflation, the mortgage rate you pay will fluctuate from year to year depending on economic conditions. A rise in inflation will lead to an increase in interest rates and vice versa. If you would like to pay a fixed rate of interest on your home loan, consider getting a fixed rate mortgage at a time when interest rates are low.

The rate of interest charged on home loans is also affected by the prevailing rate of inflation. However, only adjustable rate mortgages (ARMs) can be affected by inflation. If you apply for an adjustable rate mortgage, which is adjusted annually for inflation, the mortgage rate you pay will fluctuate from year to year depending on economic conditions. A rise in inflation will lead to an increase in interest rates and vice versa. If you would like to pay a fixed rate of interest on your home loan, consider getting a fixed rate mortgage at a time when interest rates are low.

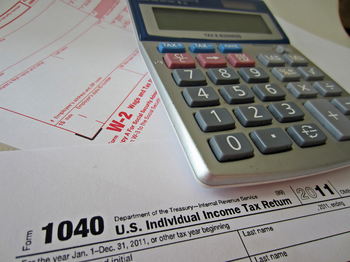

Many small and medium entrepreneurs make the mistake of presuming that hiring payroll companies is something that they need not even consider. They feel only big organizations that are required to comply with complicated laws and regulations relating to withholding of tax and other formalities need to hire such firms. All businesses, irrespective of their size or market capitalization, are required to comply with certain tax rules and formalities. Presuming that payroll services are something that only big companies need to bother with can prove to be a very significant mistake on your part.

Many small and medium entrepreneurs make the mistake of presuming that hiring payroll companies is something that they need not even consider. They feel only big organizations that are required to comply with complicated laws and regulations relating to withholding of tax and other formalities need to hire such firms. All businesses, irrespective of their size or market capitalization, are required to comply with certain tax rules and formalities. Presuming that payroll services are something that only big companies need to bother with can prove to be a very significant mistake on your part.

Thirdly, strategic assistance will also compare various new technologies to identify the option that will serve your firm best in the long run. Should you invest in technologies that will help you leverage wearable technologies? Will your decision to focus on such an option help you enjoy long-term benefits? Or, should you wait for the technology to become more common before upgrading your IT platform? With so many exciting options at your disposal, it is important to adopt a logical and rational approach when comparing options and finalizing your strategy.

Thirdly, strategic assistance will also compare various new technologies to identify the option that will serve your firm best in the long run. Should you invest in technologies that will help you leverage wearable technologies? Will your decision to focus on such an option help you enjoy long-term benefits? Or, should you wait for the technology to become more common before upgrading your IT platform? With so many exciting options at your disposal, it is important to adopt a logical and rational approach when comparing options and finalizing your strategy.

Your personality must be taken into account. Each individual will have a unique set of criteria on which to base the ideal temporary quarters. Are you okay with noisy places and large crowds? If you’re the type that likes to be where the action is, then a spot along the western portion of the island is a must. This is where the capital is located along with the finest establishments. It is the hub of activities and everything is just a stone’s throw away. If you’d rather stay in a quiet place, then the eastern side is better. Enjoy a peaceful holiday in a more secluded site.

Your personality must be taken into account. Each individual will have a unique set of criteria on which to base the ideal temporary quarters. Are you okay with noisy places and large crowds? If you’re the type that likes to be where the action is, then a spot along the western portion of the island is a must. This is where the capital is located along with the finest establishments. It is the hub of activities and everything is just a stone’s throw away. If you’d rather stay in a quiet place, then the eastern side is better. Enjoy a peaceful holiday in a more secluded site.

(1). Early Pregnancy – Urine tests are used for measuring HCG numbers early on during pregnancy. That means the HPT results will either be Positive or Negative while the blood HCG numbers lay out a specific number as mIU/ml.

(1). Early Pregnancy – Urine tests are used for measuring HCG numbers early on during pregnancy. That means the HPT results will either be Positive or Negative while the blood HCG numbers lay out a specific number as mIU/ml.