Getting The Most Of Your Plastering Contractors In Toorak

Many people make the mistake of hiring a plastering company just because it is the first one they come across.

Many people make the mistake of hiring a plastering company just because it is the first one they come across.

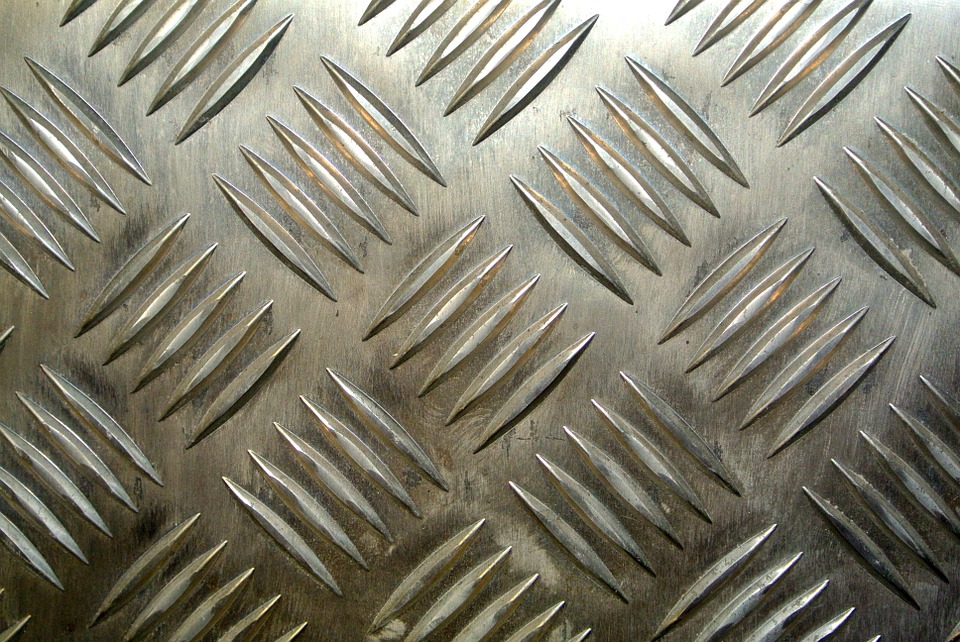

La chapa de aluminio 6061 es una de las aleaciones de la serie 6000 más utilizada. De hecho, se podría

If you are planning to buy insulated metal roof for your home in Coffs Harbour, it is important to know

The real estate market is full of different options that suit all tastes. From rustic houses and minimalist style properties

Every type of business has its own particular requirements. Designers must be able to create a plan that ticks all

Being a smart entrepreneur is all about understanding that running a profitable business is no different than leading a successful

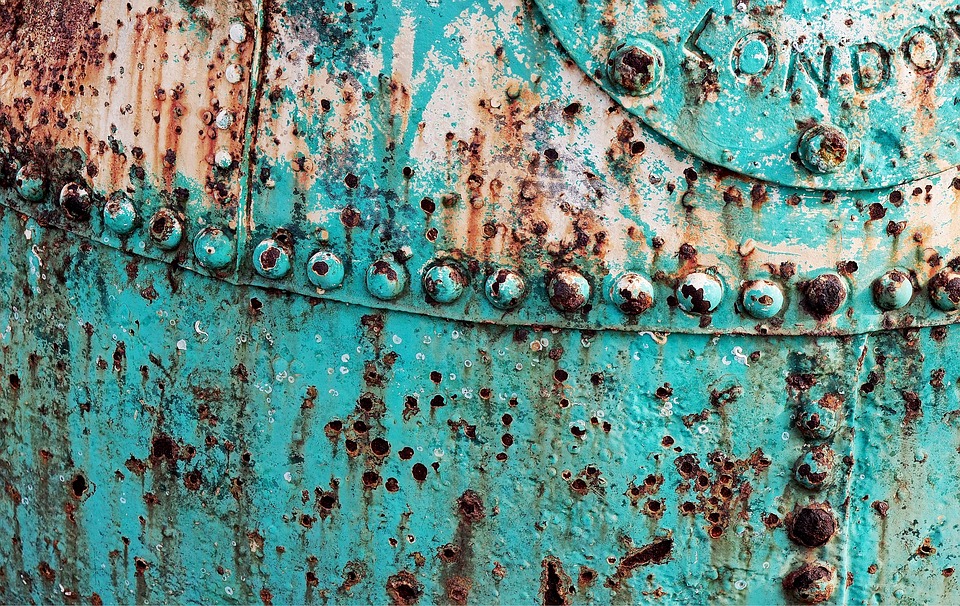

The use of metal sheets in construction and manufacturing of parts is slowly but surely overtaking the use of metal

Boca Raton Patio Pavers are an excellent type of hardscaping you can incorporate in your yard to add charm and

When it comes to steel fabrication Perth has many options. This is a method of bending, cutting and moulding steel

Industrial roofing must meet all the required specifications that are made before the project begins. This may be in terms